Metal Stamping Specialists Since 1945

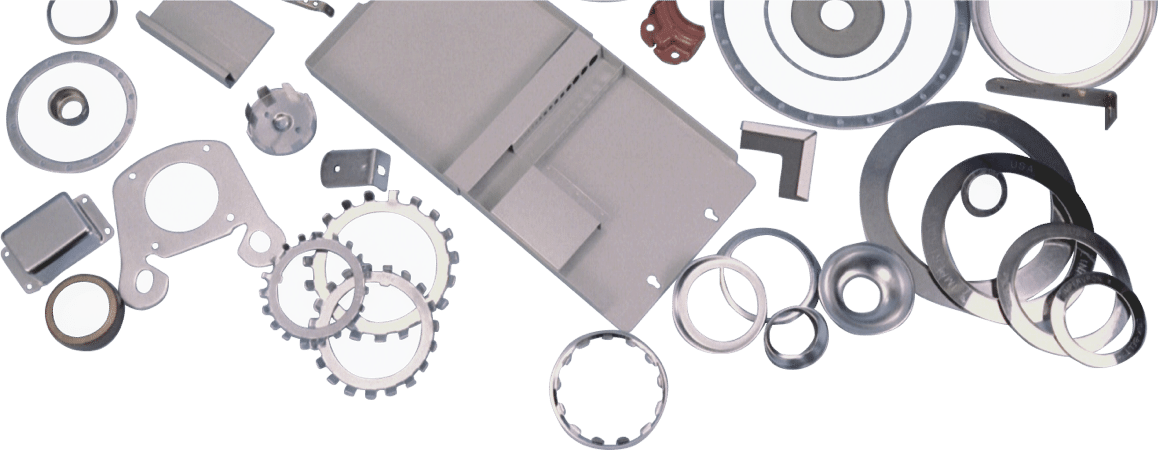

Reliable Metal Stamping Co., Inc. is your source for short, medium to high volume custom metal stampings in a full range of metals.

Metal Stamping Specialists Since 1945

Reliable Metal Stamping Co., Inc. is your source for short, medium to high volume custom metal stampings in a full range of metals.

Custom Metal Stamping Capabilities

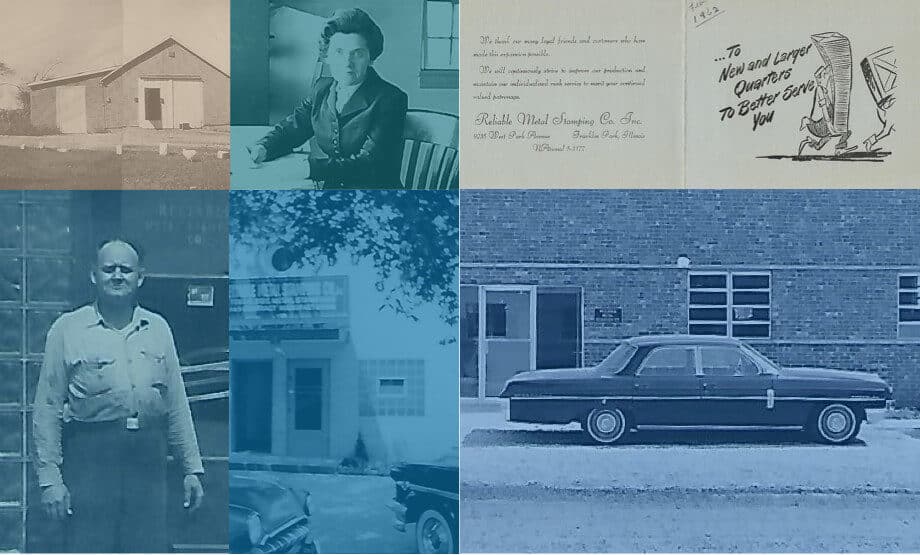

In Business Since 1945 - Family Owned & Operated for 4 Generations

Built on the strong foundation of four generations of family management, Reliable Metal Stamping, Co. Inc. is now a multi -million dollar business located minutes away from O’Hare Airport and the central transportation hub of Chicago. Even though the state of the art stamping facility has come a long way from its humble beginning in a rented corn crib, Reliable Metal Stamping Co., Inc. has never lost sight of what is important: providing quality products at fair prices.

Distributor Programs are Available for Electrical Conduit Hangers, Straps and Accessories

In addition to custom metal stampings, we offer a complete line of Electrical Conduit Hangers, Straps and Accessories that are Made In the USA