The Process

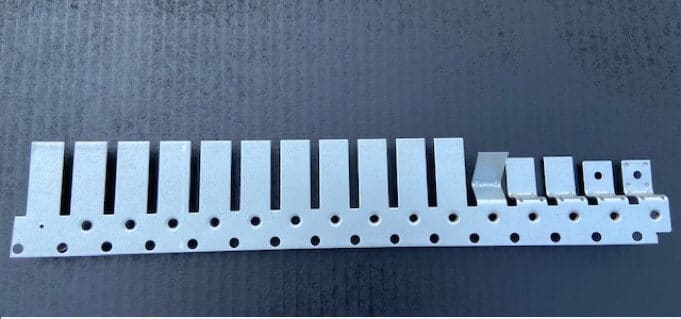

Progressive metal stamping is a complex process. With the progressive process, steel advances through different stations of the die. Depending on the complexity of the part, the number of stations is determined and could include punching, blanking, bending, coining, embossing, flanging, etc. The final result is a completed part utilizing just one die.

Common Progressive Metal Stamping Stations

Punching

Clean precise holes created with a punch press.

Bending

Accurately and consistently forms angles and complex shapes

Drawing

Transforms metal into deep shapes where depth exceeds diameter.

The Advantages of Progressive Die Stamping

Cost Effective

Streamlined Manufacturing Process

High Quality, Uniform Parts

Long Lasting Dies